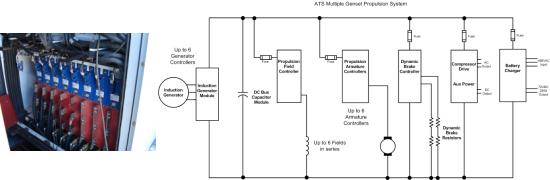

ATS now has 3 induction generator multi-genset systems in operation.

Featuring our bi-directional induction generator controller which provides constant DC bus voltage with variable speed engine control and Smokeless Starting.

ATS now has 3 induction generator multi-genset systems in operation.

Featuring our bi-directional induction generator controller which provides constant DC bus voltage with variable speed engine control and Smokeless Starting.